Why DTF Printing is the Future of Custom-made Apparel Manufacturing

Wiki Article

Developments in DTF Printing: Exactly How It's Revolutionizing the Sector

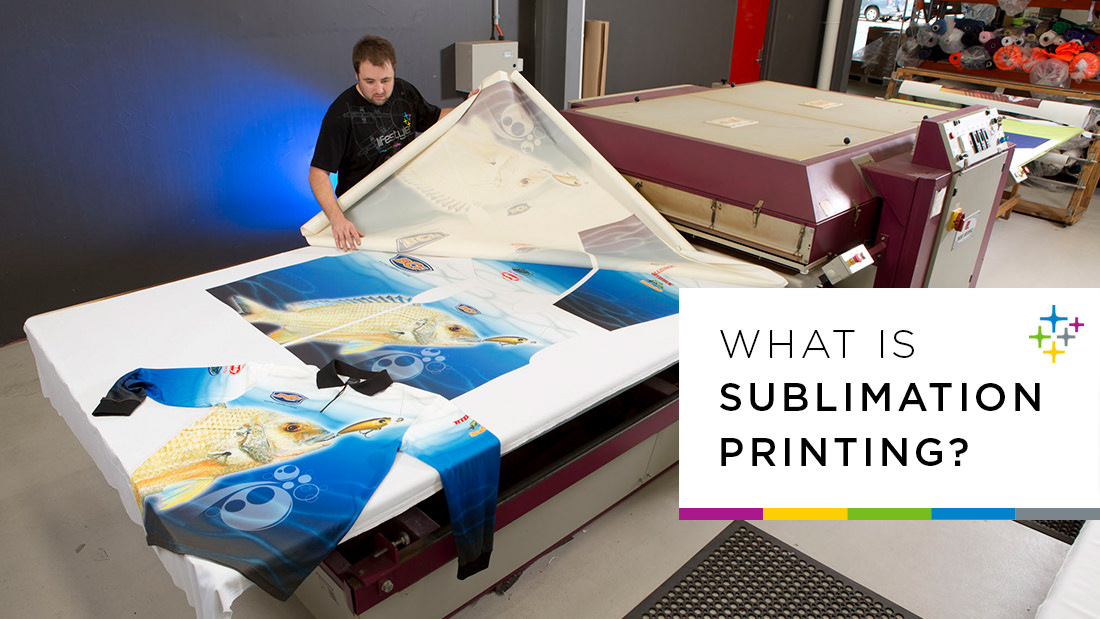

The textile printing sector is going through a significant transformation, driven by the innovative developments in Direct-to-Film (DTF) technology. These developments are not only enhancing print high quality and flexibility yet additionally enhancing the whole printing procedure. With exceptional ink formulations, enhanced movie and sticky modern technologies, and the assimilation of automation, DTF printing supplies lively, long lasting prints on a selection of fabrics, fulfilling the boosting need for modification. As companies look for extra ecologically pleasant and effective options, the implications of these advancements necessitate a closer exam right into exactly how they are forming the future of fabric printing.Improvements in DTF Innovation

Progressing quickly, DTF (Direct-to-Film) printing modern technology has gone through substantial enhancements that are reinventing the textile sector. One of the most notable developments is the enhancement in print quality. Modern DTF printers utilize sophisticated ink formulas that cause vivid, resilient prints with high resolution and color accuracy. These inks are especially crafted for compatibility with numerous material kinds, guaranteeing regular high quality despite the product.

Additionally, developments in film and sticky technologies have actually boosted the total application process. New movies supply better elasticity and bond, improving the resilience and washability of the published styles - sublimation printing. This makes sure that the prints keep their honesty and vibrancy also after several washes

Finally, environmental factors to consider have actually prompted the advancement of environment-friendly DTF options. Suppliers are progressively taking on sustainable techniques, such as using recyclable movies and water-based inks, lining up with international initiatives to decrease the industry's environmental footprint.

Benefits Over Typical Techniques

When comparing DTF printing to conventional techniques such as display printing and direct-to-garment (DTG) printing, several unique advantages emerge. heat transfer vinyl printing. One of one of the most significant benefits is its versatility in fabric compatibility. Unlike screen printing, which commonly requires details textile types, DTF printing can be put on a wider series of products, consisting of cotton, polyester, and blends, without endangering print top qualityOne more remarkable benefit is cost-effectiveness, particularly for tiny to medium-sized orders. Typical display printing ends up being financially sensible just at higher quantities as a result of the configuration prices involved. In comparison, DTF printing gets rid of these configuration expenses, making it a lot more inexpensive for smaller sized batches and one-off designs.

Additionally, DTF printing excels in longevity and washability. Additionally, DTF printing uses faster turnaround times.

Enhanced Design Capacities

DTF printing offers enhanced layout abilities that establish it apart from traditional printing approaches. The process entails printing a design onto a special film, which is after that moved to fabric.Moreover, DTF printing sustains a large selection of fabrics, including cotton, polyester, blends, and also non-textile substratums. This flexibility opens up doors for imaginative applications in varied sectors such as fashion, home style, and advertising products. Unlike display printing, which can be limiting as a result of shade separation and stencil creation, DTF printing simplifies the process, making photo-realistic and multi-color styles a lot more available.

Additionally, DTF printing succeeds in achieving constant color precision and vibrancy. In essence, DTF printing encourages developers to push the borders of creative thinking, delivering visually magnificent outcomes that were formerly unattainable.

Expense and Time Efficiency

One of the significant advantages of DTF printing lies in its cost and time efficiency, making it a recommended option for several services. Unlike standard techniques that need significant financial investment in displays and setup times, DTF printing permits for straight application onto numerous materials with marginal prep work.Moreover, DTF printing masters producing brief runs and personalized orders cost-effectively. The capacity to generate top quality prints without the need for big quantity dedications decreases waste and maximizes resource allowance. This versatility is particularly helpful for local business and start-ups that may not have the capital to spend in large-scale manufacturing runs.

In regards to operational efficiency, DTF printing's structured process boosts total performance. The innovation's compatibility with a variety of substrates and fabrics better expands its application extent, lowering the demand for several printing systems. Subsequently, businesses can achieve a faster turnaround time, boosting customer complete satisfaction and competition on the market. Therefore, DTF printing sticks out as a transformative option in the printing industry.

Future Trends in DTF Printing

Expecting future trends in DTF printing exposes a landscape noted by fast technical advancements and boosted market demand (sublimation printing). One considerable pattern is the integration of fabricated intelligence (AI) and maker understanding algorithms to maximize print top quality and streamline operations. AI-driven systems can forecast potential problems and change settings in real-time, making sure consistently top quality resultIn addition, improvements in eco-friendly inks and sustainable products are anticipated to gain traction. As ecological concerns end up being a sublimation printing lot more important, the market is likely to see a shift in the direction of eco-friendly and non-toxic inks, decreasing its eco-friendly footprint.

Modification and personalization will certainly also play an essential duty. With the growing consumer demand for unique, customized items, DTF printing modern technologies are advancing to offer more complex and thorough personalization alternatives. This pattern is sustained by boosted software options that enable for more facility and innovative designs.

Lastly, the integration of DTF printing with other digital platforms and ecommerce options will come to be more seamless. This connectivity will certainly make it possible for services to supply on-demand printing services directly to customers, additionally driving development in the sector. These trends jointly highlight a future where DTF printing not just fulfills yet surpasses the progressing demands of the market.

Conclusion

When contrasting DTF printing to traditional techniques such as display printing and direct-to-garment (DTG) printing, a number of unique benefits emerge. Unlike screen printing, which frequently needs certain textile kinds, DTF printing can be used to a broader variety of products, including cotton, polyester, and blends, without endangering print top quality.

DTF printing offers enhanced design capabilities that establish it apart from traditional printing methods. Hence, DTF printing stands out as a transformative service in the printing industry.

Developments in DTF printing considerably boost the textile printing sector by supplying remarkable print convenience, quality, and efficiency.

Report this wiki page